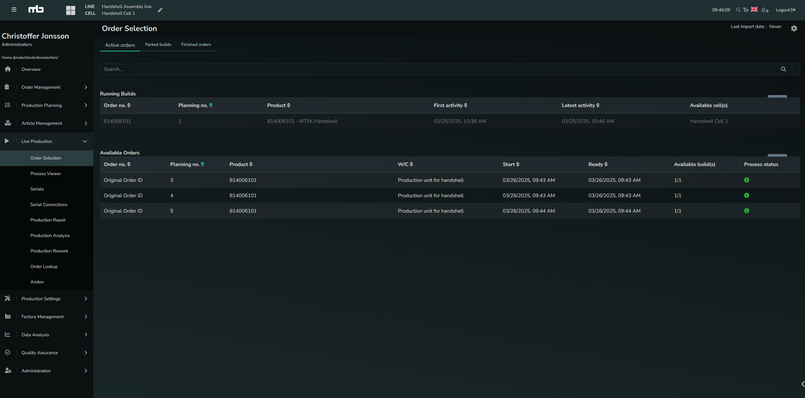

MBrain’s Process Viewer & Order Selection feature streamlines production operations by providing a digital interface for managing work instructions and selecting production orders. It enables operators to efficiently navigate tasks, track order progress, and ensure process consistency.

Key Capabilities:

Highly Configurable Operator Interface – The process viewer allows skill based views, integrating work instructions, takt time, disturbance reporting, and quality validation.

Support for Multiple Media Formats – Users can upload and display PDFs, videos, GIFs, images, and interactive instructions to support production processes.

Digital Work Instructions – Instructions can be customized using no-code GUI based tools, ensuring clarity and precision in execution.

Process Step Validation & Authorization – Some steps require validation from qualified operators, ensuring quality control and traceability.

Automatic & Manual Order Selection – Orders can be manually selected, automatically loaded, created Kanban-style and/or started using a barcode scanner.

Andon & Disturbance Reporting – Operators can report process issues, trigger Andon calls, and log interferences for continuous improvement.

Timed Process Steps – Each process step is timed and the operator is continuously shown how they are doing in relation to the planned time, and what steps are next. The timing is always saved for later analysis, and can trigger Andons and Interference reports automatically.

Serial Number Connections – Process Viewer allows (and sometimes demands) the Operators to attach serial numbers to builds which creates detailed traceability hierarchies and records.

Integration of Tools – Process Viewer supports integrations to devices, like for instance Atlas Copco Torque Driver, where users are guided through tightening screws in the correct order with automatic recipe handling. Additionally it supports re-tightening protocols in case of non-approved tightening. Results are always saved in the traceability records.

How It Works in MBrain:

Order Selection – Operators can manually select production orders from a list, with options to reset, park, or restore orders.

Automatic Order Loading – MBrain automatically starts the next planned order based on line and cell priorities.

Barcode-Based Start – Operators can scan a serial number to initiate a process step, ensuring traceability and flexible workflow control.

Instruction Display – Digital work instructions, including text, images, videos, and interactive elements, guide operators through tasks.

Process Execution & Validation – Operators complete tasks, and in some cases, require higher-level authorization for validation.

Real-Time Monitoring & Alerts – The system logs order progress, tracks deviations, and allows immediate response to issues.

MBrain’s Process Viewer & Order Selection feature enhances efficiency, quality control, and traceability, enabling manufacturers to maintain consistent and optimized production flows.